Valensa

Crystalline Glaze Tiles

Customize Your Crystalline Glaze Tiles

Porcelain Tile Manufacturer for Commercial &Project Supply

EN14411/ ISO13006 Compliant Cloudy Vein Stone Tiles for AU. EU. UK Markets

Valensa Ceramics is an export-oriented porcelain tile manufacturer based in Foshan, China, supplying commercial wall and floor tile solutions for distributors and project teams across Australia, the European Union, and the United Kingdom. With more than 20 years of continuous manufacturing experience, we focus on project suitability, standard compliance, and long-term supply stability. Our approach supports specification review, tender evaluation, and phased project delivery rather than one-off spot purchasing.

Why Choose Valensa as Your Cloudy Vein Stone Porcelain Tiles Manufacturer ?

Foshan Manufacturing Facility

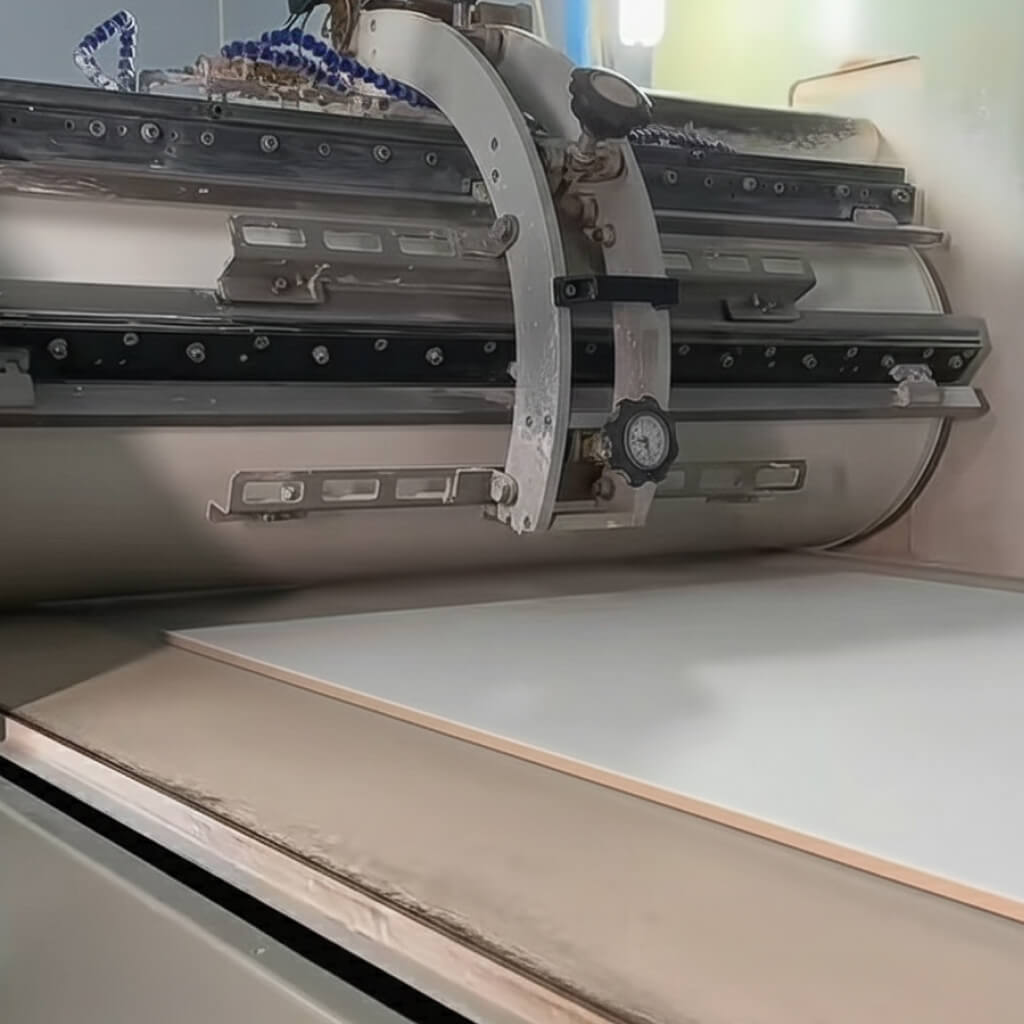

Valensa operates an integrated porcelain tile manufacturing facility in Foshan, China—one of the world’s most established ceramic production hubs.

Six automated production lines

Approximate daily production capacity of 90,000 m²

In-house processes covering forming,glazing, kiln firing, inspection, and packing

This production scale enables reliable support for continuous replenishment, phased project supply, and batch-to-batch consistency, which are essential requirements for commercial and public-space projects.

We do not aim to cover every tile application.Our long-term focus is on:

Overseas residential, apartment, and commercial public spaces

Medium- to large-scale continuous floor areas

Projects where batch consistency, long-term appearance, and delivery stability are critical

We operate as an engineering-oriented tile manufacturer, not a factory driven by seasonal trends or short-term decorative appeal.

Export Experience in AU / EU / UK Projects

Our products are exported to more than 40 countries, with long-term cooperation across Australia, Europe, and the United Kingdom. Typical applications include:

- Hotel and hospitality interiors

- Commercial lobbies and office reception areas

- Retail feature walls and public decorative spaces

Many distributors and engineering partners have worked with us for 10 to 20 years, primarily due to predictable technical performance, clear documentation, and stable delivery schedules.

Cloudy Vein Stone Porcelian Tiles for Commercial & Project Applications

A Large-Area Stone-Look Porcelain Solution Built on the Engineering Stability–First Model

Cloudy Vein Stone is not designed to impress at first glance.

It is developed based on an internal methodology refined through long-term project delivery—Engineering Stability–First Model

Control risk first. Aesthetics follow.

Cloudy Vein Stone is commonly specified for:

Villa interiors

Public spaces

Commercial areas

The Engineering Stability–First Model

When evaluating whether a product is suitable for an engineering project, we focus on three result-driven risk indicators:

① Rework Risk

Will the tile be rejected after large-area installation due to pattern repetition or lighting issues?

② Replenishment Consistency Risk

Can visual continuity be maintained during 12–18 months of phased delivery?

③ One-Year Appearance Stability

After real use, cleaning, and foot traffic, does the space still appear balanced and refined?

Cloudy Vein Stone consistently performs well across all three criteria.

Wall & Floor Porcelain Tiles for Commercial Use

Our standard porcelain tile ranges are suitable for commercial wall and floor applications, offering stable color control, controlled dimensional tolerances, and consistency for large-area installations.

Large-Format & OEM Development Capability

Supported by in-house R&D, we provide large-format tiles and OEM or private-label development to meet distributor branding needs and project-specific design requirements.

What Is Cloudy Vein Stone Porcelian Tiles Technology?

A New Generation of High-Performance Surfaces Powered by Digital Precision

In today’s high-end architectural and interior design market, surface materials are no longer judged by appearance alone. Designers and project owners now demand authentic texture, long-term durability, functional performance, and sustainable value.

VALENSA Cloud Vein Stone porcelain tiles were developed to meet these evolving expectations. Rather than simply imitating natural stone, Cloud Vein Stone re-engineers its essence through advanced digital manufacturing—delivering a surface that excels in visual depth, tactile realism, and technical performance.

Core Technology System

Cloud Vein Stone Porcelian Tiles are the result of an integrated technology system, not a single decorative process. Its performance and realism are built on four key innovations:

1.Digital Cloud Vein High-Hardness Glaze Technology

By combining high-density, high-hardness glazes with precision-formulated sculpted inks, this technology creates dense, durable surfaces while enabling multi-layered stone textures. It forms the structural foundation for both high realism and superior stain resistance.

2.3D Positioning Interactive Hybrid Sintering Technology

Digital textures are precisely aligned with physical surface structures. Specialized dry granules are selectively applied to designated pattern zones and interact chemically with the base glaze during firing, enhancing crystal depth, translucency, and three-dimensional layering.

3.Sculpted Ink & Precision Mold System

Micron-level precision molds are applied while the glaze remains unfired, embossing textures that correspond exactly to the printed pattern. This ensures complete alignment between visual appearance and tactile sensation, far beyond conventional flat digital tiles.

4.Wax Polishing Process

Unlike traditional high-gloss polishing, wax polishing uses soft abrasive media infused with micro-wax elements. This refines the surface, seals micro-pores, and creates a soft matte finish with a warm, stone-like touch, while further improving scratch and stain resistance.

Key Performance Specifications

Designed for Long-Term Use, Not Just Visual Impact. Cloud Vein Stone tiles are engineered to meet demanding residential and commercial requirements:

- Water Absorption ≤ 0.5%

Resulting in extremely low permeability, easy maintenance, and exceptional long-term stability. - Mohs Surface Hardness ≥ Level 5

Higher than typical ceramic tiles, offering excellent resistance to abrasion and scratching in high-traffic environments. - Slip Resistance: R10–R11 (Dry / Wet Conditions)

Meets safety standards for slip resistance, making it ideal for bathrooms, kitchens, balconies, and other wet areas. - Gloss Level: 15–20° Soft Matte

Diffused light reflection reduces glare and visual fatigue, creating a refined, calm, and premium spatial atmosphere. - Stain Resistance: Level 5 (Highest Grade)

Dense glazed surfaces effectively resist common stains such as tea, coffee, soy sauce, and ink—easy to clean with minimal maintenance.

Architectural Visual Effect

The result is a surface with real micro-relief texture that aligns with the stone pattern, rather than a flat printed appearance.

We go beyond crafting premium tiles with meticulous expertise, along with a diverse range of sizes — including 600×1200mm, 700×1500mm, 900x1800mm ( provide custom service ) — to precisely match the needs of every space.”

Providing flexible and versatile solutions for a wide range of design styles, including modern minimalism, Wabi-Sabi, and industrial aesthetics. From raw material sourcing to production, VALENSA consistently upholds a commitment to sustainability, reducing reliance on natural stone through environmentally responsible processes—allowing luxury and nature to coexist in harmony.

- Cloudy Vein Stone Tiles (600x1200mm/700x1500mm/900x1800mm)

Cloudy Vein Stone Porcelain Tiles Key Benefits for Commercial Projects

The following are not marketing claims, but conclusions repeatedly confirmed during post-project reviews:

1. In continuous installations of 800–1500 m²

Compared with standard stone-look tiles, Cloudy Vein Stone shows significantly fewer detectable repetition points, which is essential in public and shared spaces.

2. After 6–12 months of real-world use

The soft-matte surface combined with subtle 3D texture results in: Better visual recovery after cleaning Fewer complaints about surfaces appearing “dirty” or “aged”

3. In phased engineering projects

Through project-based production and retained reference samples,complaints related to color variation during replenishment are substantially reduced.

These outcomes explain why Cloudy Vein Stone continues to be specified in engineering projects.

Why Cloudy Vein Stone Porcelain Tiles Remain Stable Over Time

① Designed for Large-Area Continuity

Digital Cloud Vein Hard Glaze, combined with 3D positioning firing,allows the pattern to integrate into the glaze layer rather than sit on the surface.

Result:

Individual tiles remain understated

The overall floor reads naturally, closer to real stone

② Designed for Real Lighting Conditions

A controlled ~28° soft-light surface reduces glare under both daylight and artificial lighting,a common challenge in commercial and public interiors.

③ Designed for Tactile–Visual Consistency

The micro-relief texture follows the vein direction,avoiding the mismatch of a “stone look with a glassy feel.”

|

Criteria |

Cloudy Vein Stone |

Standard Stone-Look Tile |

Natural Stone |

|

Large-area appearance |

Stable, natural |

Repetition visible |

Natural |

|

Engineering controllability |

High |

Medium |

Low |

|

Replenishment consistency |

Controllable |

Limited |

Uncontrollable |

|

Appearance after 1 year |

Stable |

Ages quickly |

Requires maintenance |

|

Overall project risk |

Low |

Medium |

High |

Typical Applications

Cloudy Vein Stone porcelain tiles, defined by their distinctive natural aesthetics of authenticity, warmth, and softness, combined with robust physical and chemical performance, have become a core surface material for creating refined flooring and wall applications in high-end spaces.

Suitable for full-scale applications—from commercial lobbies and luxury hotels to villa living rooms, TV feature walls, kitchen islands, corridors, bedrooms, and bathrooms—Cloud Vein Stone porcelain tiles adapt seamlessly to diverse environments. Through its precisely sculpted textures and 28° soft-light finish, it integrates effortlessly with a wide range of design styles, including modern minimalism, wabi-sabi naturalism, and refined Oriental luxury.

Offering a systematic, wall-to-floor integrated solution encompassing main tiles, molded elements, and decorative patterns, Cloudy Vein Stone porcelain tiles capture the poetic grandeur and premium tactile quality of natural stone while ensuring exceptional durability and long-term comfort.

Not recommended for: Outdoor exposure for long time / Short-term or budget-driven projects

Maintenance & Cleaning

Thanks to its dense, high-hardness glazed surface, Cloud Vein Stone porcelain tiles are exceptionally easy to maintain. The key lies in using proper, gentle cleaning methods.

For daily care, simply wipe the surface with a soft dry cloth or a well-wrung damp cloth to keep it clean. When a cleaning agent is required, always choose a neutral or tile-specific cleaner, and strictly avoid abrasive tools such as steel wool, as well as acidic or alkaline cleaners (e.g., toilet cleaners), which may scratch or chemically damage the tile’s distinctive soft-matte finish.

With regular cleaning and proper joint maintenance, Cloud Vein Stone tiles will retain their refined appearance of authenticity, warmth, and softness over the long term.

Routine cleaning with neutral detergent and clean water

Avoid prolonged exposure to strong acids or alkalis

No sealing required under normal indoor conditions

Periodic deep cleaning recommended for commercial environments

Overall, Cloud Vein Stone porcelain tiles are easier to maintain than natural stone and less prone to showing dirt than polished tiles, making them a low-maintenance ceramic tile option.

Standards & Project Support

Base standards: porcelain and sintered stone standards (e.g. EN 14411, where applicable),Available documentation:

Technical data sheets

Slip resistance and wear test reports (market-specific)

Project submission and internal approval materials

Cloudy Vein Stone Porcelain Tiles Quality Control for Project Reliability

Full-Process Quality Management

Quality control is implemented throughout all production stages, including:

Incoming raw material inspection

In-process checks during forming,glazing, and firing

Final inspection prior to packing and shipment

This system ensures both visual consistency and technical stability across production batches.

In engineering cooperation, we focus on three control points:

Raw material and glaze batch consistency

Dimensional flatness and color checks during production

Retained project samples for future replenishment reference

If project conditions change (area, lighting, installation method),we reconfirm suitability instead of proceeding by default.

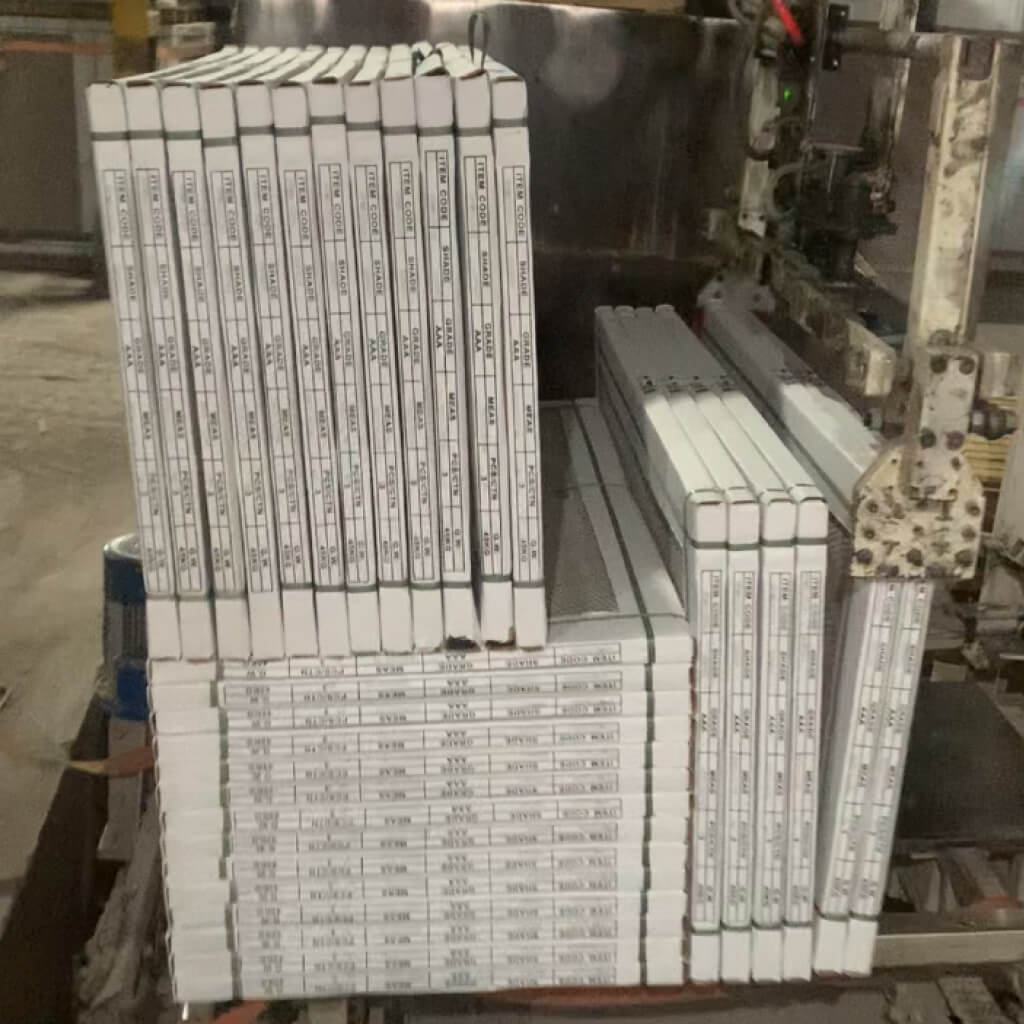

Professional-Grade Packing System:Engineering Every Layer of Protection for Flawless Delivery

We view packing as the final step of our production line and the first step of your delivery experience. For this reason, we have developed the "Porcelain, Treasured as Art" Packing System — a process exceeding industry standards. Through meticulous craftsmanship, we safeguard every inch of your tiles, ensuring they arrive at your project site in perfect condition.

Impact-Resistant Packaging More Than Cushioning — It's Structural Protection

Modularized Packing Scientific Organization for Efficient Receiving and Installation

Clear Identification System Instant Information, Full Traceability

The flawless condition you see upon unboxing is not a matter of luck -it is the guaranteed result of our systematic, multi-layered protection.

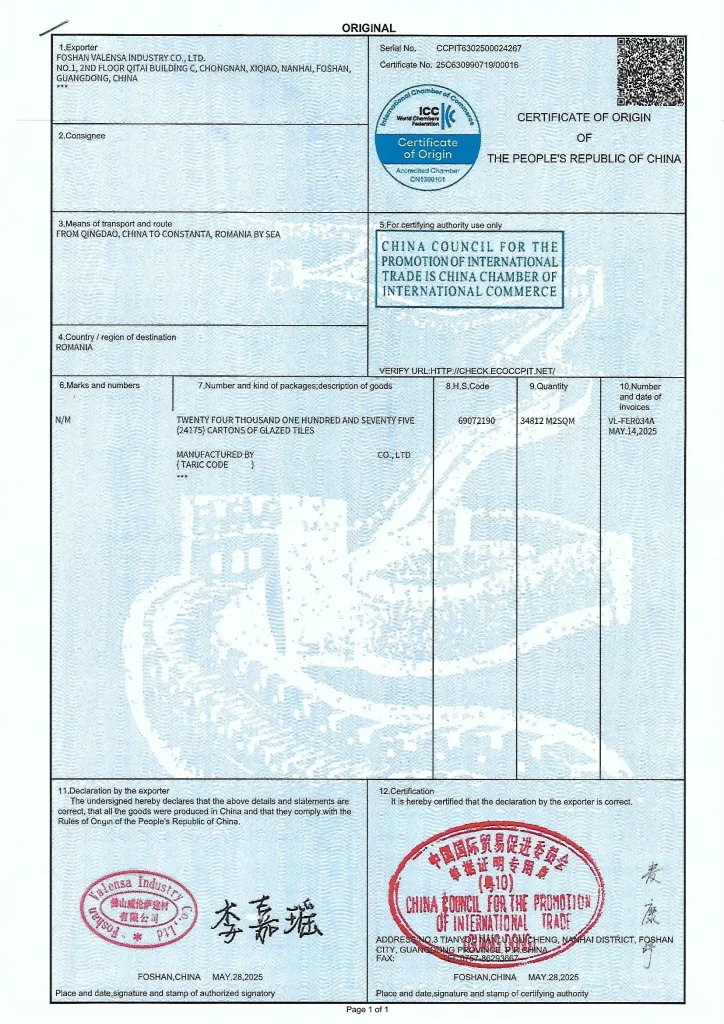

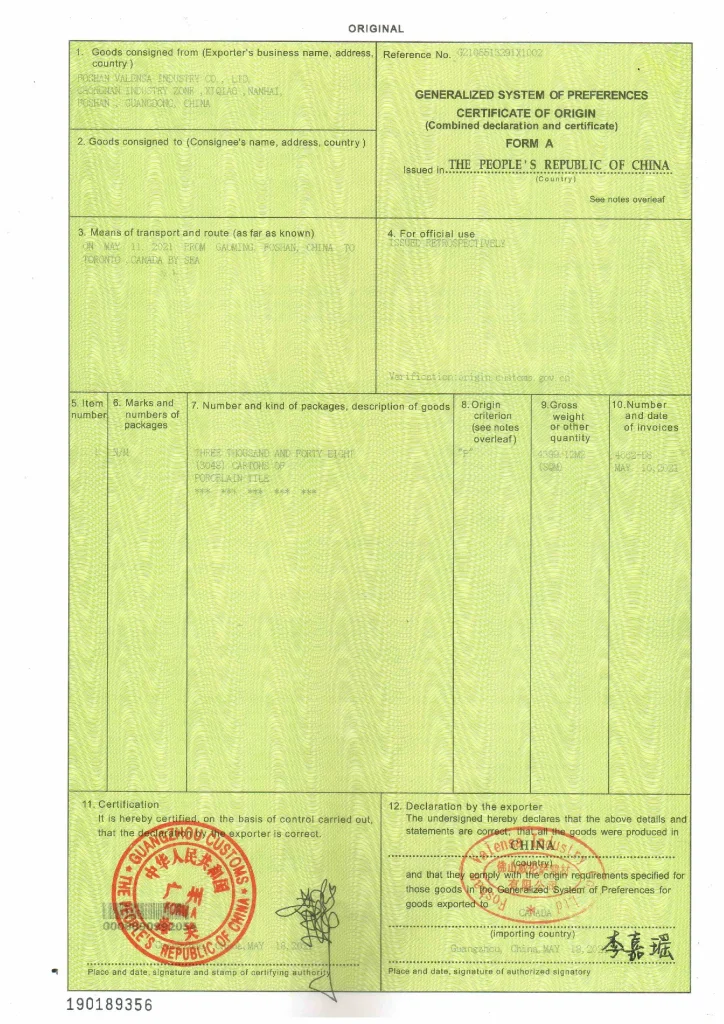

Our Certification & Documentation Support

Certifications

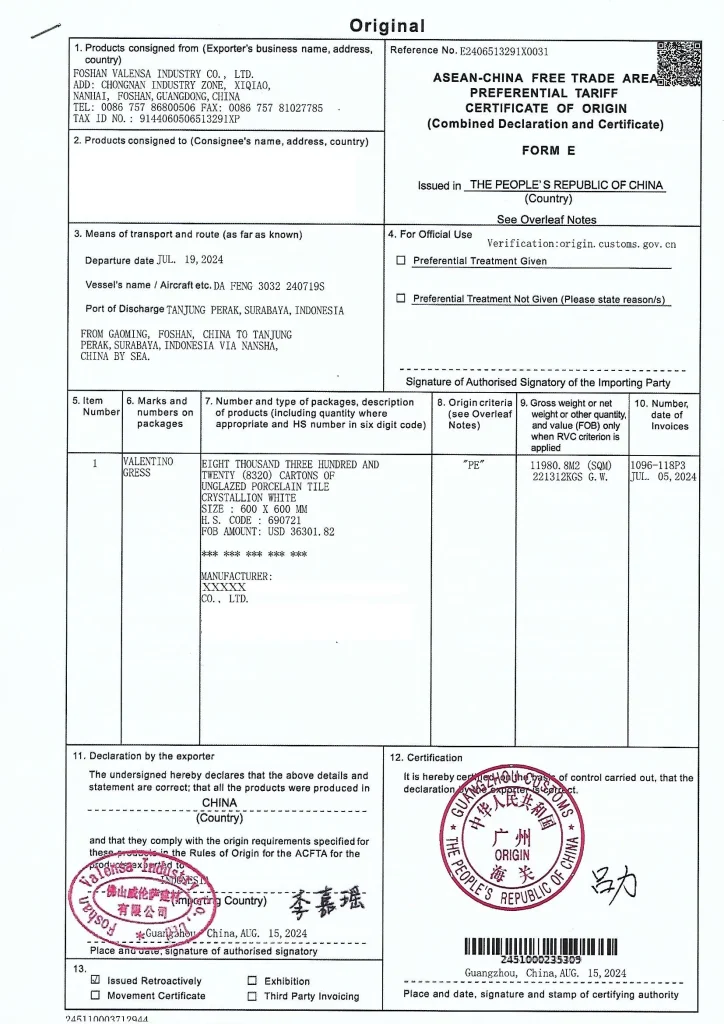

CO

FORM A

FORM E

FUMIGATION

ISO-R

Technical Documentation for AU / EU / UK Projects

For project and procurement use, we provide:

- EN14411/ ISO13006-aligned technical datasheets

- Available third-party test reports (for selected series)

- Product samples for material assessment

Cooperation Models for Distributors & Project Teams

For Distributors

- Minimum order quantity from one container

- Stable supply programs for repeat orders

- OEM and private-label support

For Project & Engineering Teams

- Batch consistency for phased delivery

- Technical documentation for specification and tender review

- Installation guidance and warranty support

Before final approval, physical samples (dry and wet), testing requirements, and maintenance conditions should be carefully reviewed.

Contact us to request samples, technical data, or project-specific recommendations.

FAQ

1. What do you actually mean by “porcelain tiles”?

People use the term porcelain tile very loosely.

For us, it means one simple thing first:

water absorption of 0.5% or lower.

Why does this matter?

Because in many projects we’ve seen, tiles looked good, passed basic checks, but later failed because they absorbed too much moisture over time.

Low absorption doesn’t solve every problem — but without it, problems are much more likely.

2. Are porcelain tiles suitable for outdoor use?

Yes — if the surface and system are right.

In our experience, outdoor problems usually happen when:

polished or smooth tiles are used outside

drainage isn’t clearly planned

slope is ignored

When those things are overlooked, the result is often complaints, safety concerns, or even replacement.

That’s why we usually recommend textured or matt surfaces for outdoor areas.

3. What about porcelain tiles in frost and cold climates?

People often ask if porcelain tiles are “frost-proof”.

From what we’ve seen, frost damage almost never starts with the tile itself.

It starts with water trapped under or inside the system.

Low absorption helps, but proper drainage and installation matter just as much.

4. Are porcelain tiles better than ceramic tiles for commercial projects?

In most commercial situations — yes.

We’ve seen ceramic tiles used in public areas to save cost, only to be replaced a few years later due to:

- moisture issues

- edge damage

- inconsistent appearance after wear

Porcelain tiles are simply more forgiving over time.

5. Can porcelain tiles be used for driveways?

They can — but this is where mistakes are expensive.

Most failures we’ve seen were not about the tile, but about:

- base preparation

- load assumptions

- edge restraint

Approving the tile without confirming the whole system is risky.

6. Are porcelain tiles easy to maintain?

They can be — if expectations are realistic.

Textured outdoor tiles need periodic deep cleaning.

Polished tiles need careful maintenance to keep their appearance.

Many complaints we hear are actually maintenance issues, not product defects.

7.Is Glue Dry-Granule Right for Your Project?

Glue dry-granule sintered stone is best suited for projects that require:

A natural stone appearance

Reduced surface glare

Long-term visual and performance stability

Controlled anti-slip characteristics

Porcelain Tile Manufacturer for Commercial &Project Supply

EN14411/ ISO13006 Compliant Crystalline Glaze Tiles for AU. EU. UK Markets

Valensa Ceramics is an export-oriented porcelain tile manufacturer based in Foshan, China, supplying commercial wall andfloor tile solutions for distributors and project teams across Australia,the European Union, and the United Kingdom.With more than 20 years of continuous manufacturing experience, we focus on project suitability, standard compliance, andlong-term supply stability.Our approach supports specification review, tender evaluation, and phased project deliveryrather than one-off spot purchasing.

Why Choose Valensa as Your Crystalline Glaze Tiles Manufacturer

Foshan Manufacturing Facility

Valensa operates an integrated porcelain tile manufacturing facility in Foshan, China-one of the world's most establishedceramic production hubs.

Six automated production lines

Approximate daily production capacityof 90,000 m2

In-house processes covering forming,glazing, kiln firing, inspection, and packing

This production scale enables reliable support for continuous replenishment, phased project supply, and batch-to-batchconsistency, which are essential requirements for commercial and public-space projects.

Export Experience in AU / EU / UK Projects

Our products are exported to more than 40 countries, with long-term cooperation across Australia, Europe, and the UnitedKingdom. Typical applications include:

- Hotel and hospitality interiors

- Commercial lobbies and office reception areas

- Retail feature walls and public decorative spaces

Many distributors and engineering partners have worked with us for 10 to20 years, primarily due to predictable technicalperformance, clear documentation, and stable delivery schedules.

Crystalline Glaze Tiles for Commercial & Project Applications

Crystalline Glaze Porcelain Tiles - Feature and Statement Surfaces

Valensa crystalline glaze porcelain tiles are developed for architectural feature walls and focal surfaces where visual depthand long-term material stability are both required.

They are commonly specified for:

Hotel lobby feature walls

Retail brand statement areas

Large-format decorative panels in interiors

Wall & Floor Porcelain Tiles for Commercial Use

Our standard porcelain tile ranges are suitable for commercial wall and floor applications, offering stable color control,controlled dimensional tolerances, and consistency for large-area installations.

Large-Format & OEM Development Capability

Supported by in-house R&D, we provide large-format tiles and OEM or private-label development to meet distributorbranding needs and project-specific design requirements.

Crystalline Glaze Technology - Controlled Decorative Performance

Kiln-Formed Crystallization Process

Crystalline glaze tiles are produced through a controlled high-temperature kiln crystallization process, during whichcrystalline structures naturally form within the glaze layer during firing.

Unlike printed or surface-applied effects, the crystalline texture develops as part of the fring cycle itself. Each tile thereforedisplays natural visual variation,while core physical properties remain under controlled production parameters suitable forproject use.

Architectural Visual Effect

Under changing lighting conditions, the glaze surface reveals layered light and shadow effects. This characteristic makescrystalline glaze tiles particularly suitable for large-format feature applications in commercial interiors.

We go beyond crafting premium tiles with meticulous expertise, offering both positioned crystallization and full crystal-lization processes, along with a diverse range of sizes-including 600x1200x10mm, 700x1500x10mm, and1200x2700x9mm -to precisely match the needs of every space."

- Positioned Crystalline Glaze Porcelain Tiles (600x1200mm/700x1500mm/900x1800mm)

- Full Crystalline Glaze Porcelain Tiles(600x1200mm/ 700x1500mm/900x1800mm)

- Full Crystalline Glaze Sintered Stone (1200x2700x9mm)

Crystalline Glaze Technical Performance & Applicable Standards

Compliance with International Ceramic Tile Standards

Valensa porcelain tiles are manufactured and tested in accordance with internationally recognized ceramic tile standards,

including:

- EN14411

- IS013006

- Porcelain classification: Group Bla(low water absorption)

Relevant test reports can be provided to support specification,tender, and approval processes in AU, EU, and UK markets.

Key Technical Characteristics

- Water absorption: s0.1% (tested in accordance with EN/ ISO methods)

- Surface hardness: approximately Mohs 6

- Wear and stain resistance suitable for commercial interior applicationsDimensional stability maintained through controlled kiln firing

Detailed technical datasheets and test reports are available for evaluation upon request.

Practical Advantages Compared with Natural Stone

When specified for commercial interiors, crystalline glaze porcelain tiles offer:

- More consistent material structure

- Reduced sensitivity to staining and chemical cleaning agents

- Lower long-term maintenance requirements

- Predictable performance across large installed areas

These characteristics make them a practical alternative to natural stone for projects seeking decorative impact combinedwith controlled lifecycle costs.

Crystalline Glaze Quality Control for Project Reliability

Full-Process Quality Management

Quality control is implemented throughout all production stages, including:

Incoming raw material inspection

In-process checks during forming,glazing, and firing

Final inspection prior to packing and shipment

This system ensures both visual consistency and technical stability across production batches.

Real-Time Kiln Monitoring

Kiln firing parameters are monitored in real time to maintain control of key indicators such as water absorption and dimensional tolerances. This approach balances natural crystalline variation with engineering predictability.

Professional-Grade Packing System:Engineering Every Layer of Protection for Flawless Delivery

We view packing as the final step of our production line and the first step of your delivery experience. For this reason, wehave developed the "Porcelain,Treasured as Art" Packing System -a process exceeding industry standards. Throughmeticulous craftsmanship, we safeguard every inch of your tiles, ensuring they arrive at your project site in perfect condition.

Impact-Resistant PackagingMore Than Cushioning -It's Structural Protection

Modularized Packing Scientific Organization for Efficient Receiving and Installation

Clear Identification System Instant Information, Full Traceability

The flawless condition you see upon unboxing is not a matter of luck -it is the guaranteed result of our systematic, multi-layered protection.

Certification & Documentation Support

Certifications

CO

FORM A

FORM E

FUMIGATION

ISO-R

Technical Documentation for AU / EU / UK Projects

For project and procurement use, we provide:

- EN14411/ ISO13006-aligned technical datasheets

- Available third-party test reports (for selected series)

- Product samples for material assessment

Cooperation Models for Distributors & Project Teams

For Distributors

- Minimum order quantity from one container

- Stable supply programs for repeat orders

- OEM and private-label support

For Project & Engineering Teams

- Batch consistency for phased delivery

- Technical documentation for specification and tender review

- Installation guidance and warranty support

FAQ

1. What do you actually mean by “porcelain tiles”?

People use the term porcelain tile very loosely.

For us, it means one simple thing first:

water absorption of 0.5% or lower.

Why does this matter?

Because in many projects we’ve seen, tiles looked good, passed basic checks, but later failed because they absorbed too much moisture over time.

Low absorption doesn’t solve every problem — but without it, problems are much more likely.

2. Are porcelain tiles suitable for outdoor use?

Yes — if the surface and system are right.

In our experience, outdoor problems usually happen when:

polished or smooth tiles are used outside

drainage isn’t clearly planned

slope is ignored

When those things are overlooked, the result is often complaints, safety concerns, or even replacement.

That’s why we usually recommend textured or matt surfaces for outdoor areas.

3. What about porcelain tiles in frost and cold climates?

People often ask if porcelain tiles are “frost-proof”.

From what we’ve seen, frost damage almost never starts with the tile itself.

It starts with water trapped under or inside the system.

Low absorption helps, but proper drainage and installation matter just as much.

4. Are porcelain tiles better than ceramic tiles for commercial projects?

In most commercial situations — yes.

We’ve seen ceramic tiles used in public areas to save cost, only to be replaced a few years later due to:

- moisture issues

- edge damage

- inconsistent appearance after wear

Porcelain tiles are simply more forgiving over time.

5. Can porcelain tiles be used for driveways?

They can — but this is where mistakes are expensive.

Most failures we’ve seen were not about the tile, but about:

- base preparation

- load assumptions

- edge restraint

Approving the tile without confirming the whole system is risky.

6. Are porcelain tiles easy to maintain?

They can be — if expectations are realistic.

Textured outdoor tiles need periodic deep cleaning.

Polished tiles need careful maintenance to keep their appearance.

Many complaints we hear are actually maintenance issues, not product defects.