In the world of flooring and interior desian, trends evolve constantly-but one stvle that continues to grow in popularity iswood look porcelain tile. This innovative product combines the warm, organic aesthetic of natural wood with the strengthwater resistance, and low maintenance of porcelain. For homeowners, de…

BLOG

BLOG

VALENSA BLOG

Learn more about the porcelain tile industry and the latest insights from VALENSA

04

2025.12

Walk into any design studio today and you’ll hear the buzz about flexible stone. What began as a niche material hasrapidly become the secret weapon for architects and designers seeking authentic stone aesthetics without the traditionallimitations. Unlike conventional stone cladding that demands structural support ..

04

2025.12

The frst and most important step in installing any type of floor tile, whether it’s traditional ceramic or peel and stick floortile, is ensuring the subfloor is clean, flat, and dry.

27

2025.11

Keyword Focus: Sourcing Porcelain Tiles from China | China Porcelain Tile Manufacturers | Direct-from-Factory Tile Supply | 2026 Global Tile Market Trends | Porcelain Tiles from China

Introduction

Buying porcelain tiles from China has been a common sourcing strategy for wholesalers, distributors, and project buyers for many years. Competitive pricing, large production capacity, and a wide product range have made China a key global supplier.

But in 2025, many overseas buyers are asking a more cautious question: Is buying porcelain tiles from China still a good idea?

Rising logistics costs, quality concerns, and supply chain disruptions have changed how buyers think about sourcing. This article gives a clear, practical answer from a B2B buyer’s perspective—covering risks, opportunities, and what really matters when sourcing porcelain tiles from China today.

It also provides a detailed analysis of why purchasing tiles from China in 2026 remains a viable option, especially if you are working with experienced manufacturers, require large-scale orders, and prioritize production stability over price.

Looking Back at 2025, Why did China Remain One of The World’s Leading Tile Suppliers?

Despite changes in global trade, China continues to play a central role in the porcelain tile industry.

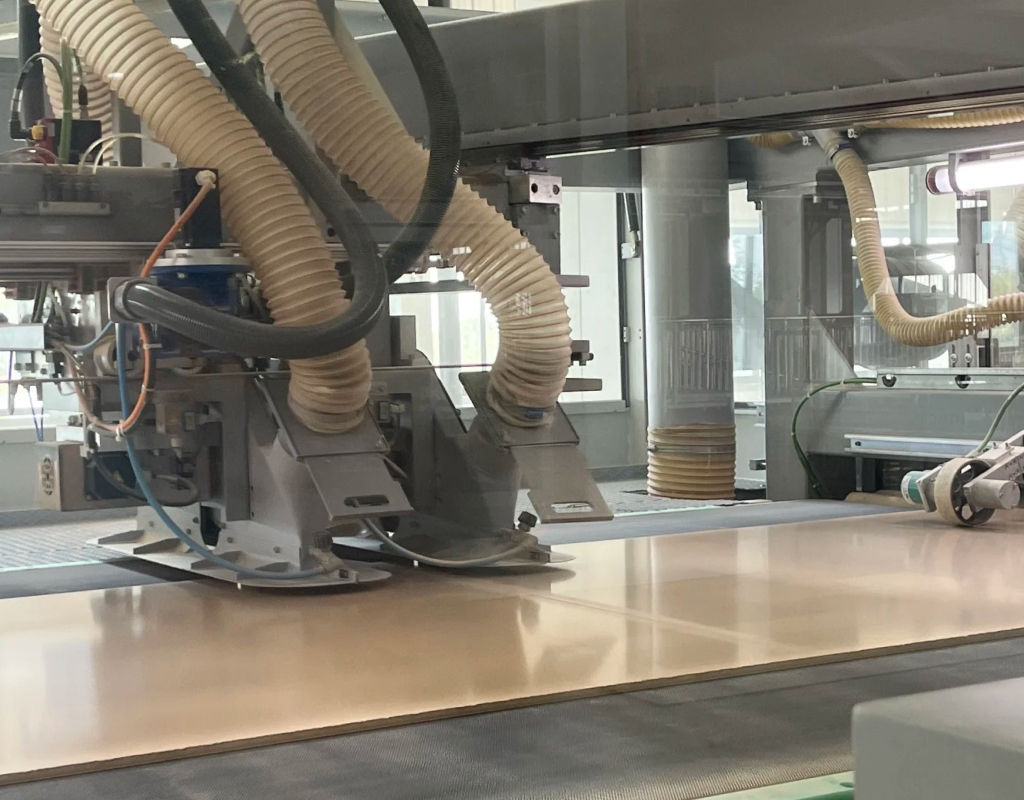

Strong Manufacturing Infrastructure

China, especially Foshan, still has one of the most complete ceramic manufacturing ecosystems in the world. Tile factories benefit from:

- Mature raw material supply chains

- Advanced kiln and glazing technology

- Skilled labor with decades of experience

These factors allow manufacturers to produce stable quality at scale, something many emerging markets still struggle to match.

Broad Product Range for Wholesale Buyers

Chinese porcelain tile factories typically offer:

- Glazed porcelain tiles

- Full body porcelain tiles

- Polished and matt finishes

- Large format tiles

- Indoor and outdoor solutions

For wholesalers, this means fewer suppliers and easier SKU expansion.

What Has Changed for Tile Buyers in 2025?

As the global economic environment evolves and export policies in various countries are adjusted, while China remains competitive, the sourcing environment is no longer the same as it was five or ten years ago.The main changes are as follows:

Price Is No Longer the Only Advantage

In the past, low unit price was the main reason buyers sourced from China. In 2025, buyers pay closer attention to:

- Delivery reliability

- Consistency between batches

- Strict product quality control

- Factory responsiveness

- Long-term cooperation potential

A cheap price means little if shipments are delayed or quality disputes arise.

From Single-Product Sourcing to Comprehensive Tile Solutions

Professional buyers today expect:

- Clear specifications

- Stable production schedules

- Transparent communication

- Basic compliance documentation

- Problem-solving capability and level of cooperation

Factories that cannot meet these expectations are quickly eliminated, regardless of price.

As market economic conditions and policy requirements across different countries continue to change, Chinese tile suppliers are required to have a solid understanding of the tile industries in different global regions, as well as relevant local policies and documentation requirements. They must keep information dynamically updated, proactively identify the materials and documents required by both parties throughout the delivery process, and be prepared to respond to unexpected situations such as changes in regulatory documentation by proposing timely solutions and cooperating actively. All of this is essential to ensuring smooth delivery of goods and safeguarding clients’ interests throughout the cooperation. This represents a comprehensive test of Chinese tile suppliers’ capabilities amid a new phase of global trade transformation and increasingly competitive market conditions.

Common Issues You Need to Know When Sourcing Porcelain Tiles From China

Buying from China is still viable—but only if buyers understand the risks and manage them correctly.The following common issues should be noted during the transaction process:

Quality Inconsistency Between Batches

One common issue is variation in:

- Shade

- Size tolerance

- Surface finish

Standard Quality Tiles VS Inferior Quality Tiles

This often happens when buyers work with suppliers that lack strict internal quality control or rely heavily on subcontracting.If a tile supplier’s product quality is inconsistent across different batches, it can lead to noticeable variations in color, texture, and gloss, which negatively affect the overall installation appearance. During construction, such inconsistencies may also cause dimensional deviations, poor flatness, and higher cutting and breakage rates, resulting in rework, increased costs, and project delays. In long-term use, differences in water absorption, strength, or slip resistance may lead to issues such as hollowing, cracking, or detachment, creating safety risks, increasing after-sales disputes, and ultimately reducing project quality and customer trust in the brand and supplier.

Unstable Lead Time and Delivery Delays

Factories without sufficient capacity or proper production planning may:

- Overpromise delivery dates

- Delay production during peak seasons

- Prioritize larger customers

This creates serious problems for wholesalers supplying retail chains or projects.Unstable delivery schedules and delayed shipments can directly disrupt construction plans, leading to work stoppages, project delays, and increased labor and management costs. They may also force clients to adopt remedial measures such as expedited shipping or temporarily switching suppliers, further driving up procurement costs. Failure to deliver in accordance with contractual terms can additionally result in breach-of-contract claims, delayed acceptance, and payment recovery risks, ultimately affecting customer satisfaction and corporate reputation, and undermining long-term cooperative relationships.

Limited After-Sales Support

Some suppliers focus only on closing the first order. When issues arise later, buyers may face:

- Slow response

- Lack of responsibility

- Poor problem-solving

Slow after-sales response and delayed issue resolution can cause a range of problems for customers. When issues are not addressed promptly, minor defects may escalate into major problems, increasing repair difficulty and costs. Delays can also disrupt project schedules and normal use, leading to late delivery, postponed occupancy, or interrupted business operations. Unresolved quality issues may further create safety risks, such as tile detachment or slippery floors. In addition, prolonged waiting and repeated communication can significantly reduce customer trust and satisfaction, making complaints, disputes, or even legal action more likely, and ultimately damaging the supplier’s brand reputation.

Additionally, as a professional tile supplier, VLAENSA recommends that during the inquiry stage you assess a factory’s reliability by asking targeted questions such as:

- “How do you control batch color variation, dimensional tolerances, and flatness?”

- “What is your standard lead time? (Please clarify whether it refers to production completion or container loading.)”

- “Are you familiar with XX import standards?”

- “How many production lines do you currently have? What is your monthly and daily production capacity?”

- “How do you communicate in case of delays? Do you have any contingency measures or compensation policies? ”

These questions help reveal the factory’s production capability, quality control level, and sense of responsibility.

How to Evaluate Whether a Chinese Tile Factory Is a Good Choice

The key question is not “Should I buy from China?”

It is “Which factory in China should I buy from?”

Assessing whether a Chinese tile factory is reliable can be focused on three key words: capability, experience, and attitude.

Factory Capability Matters More Than Factory Size

A capable tile factory is not just able to produce, but able to produce consistently, deliver on time, and control quality effectively. A reliable porcelain tile factory should demonstrate:

- Stable daily production capacity

- Clear lead time management

- In-house quality inspection

Below is a simple evaluation comparison:

| Evaluation Factor | Reliable Factory | High-Risk Supplier |

| Production lines | Self-owned, stable | Outsourced or unclear |

| MOQ policy | Flexible, transparent | Rigid or inconsistent |

| Quality control | Internal inspection system | Visual check only |

| Communication | Clear and proactive | Slow or unclear |

Experience with Long-Term Overseas Clients

Factories that serve wholesalers and project clients over many years usually:

- Understand export standards

- Anticipate common issues

- Handle disputes more professionally

Long-term cooperation history is often a stronger indicator than marketing claims.

Attitude Toward Problem Resolution

A tile company with a strong service-oriented attitude can bring customers multiple, long-term, and tangible benefits, mainly reflected in the following aspects:

Smooth communication and accurate understanding of requirements

Companies with good service attitudes are more willing to listen to customer needs and proactively communicate specifications, quality standards, delivery schedules, and application scenarios. This reduces misunderstandings and repeated confirmations, helping to avoid order or production errors.

Fast response to issues and controllable risks

When problems such as color variation, batch inconsistency, breakage, or quantity discrepancies arise, a positive service attitude means quick feedback and timely solutions, helping customers minimize losses and delays.

Easier cooperation and higher efficiency

From quotation and sampling to production and shipment, every stage is well coordinated. Customers do not need to constantly chase updates or follow up repeatedly, saving significant time and communication costs.

Reliable after-sales support and greater peace of mind

Good service attitudes are often most evident in after-sales service: no passing of responsibility, clear solutions, and reliable follow-through, giving customers greater confidence during project execution and final delivery.

In summary, capability determines whether a factory can produce quality products, experience determines whether risks can be effectively controlled, and attitude determines whether cooperation is smooth and worthy of long-term trust. Only when all three are present can a tile factory truly be considered reliable.

Project Case Reference

Here is an actual VALENSA project experience for your reference.

This year, VALENSA participated in an engineering project in the Australian market. Throughout the cooperation, we maintained efficient and close communication with the project team, working together as a highly coordinated unit. Based on the project drawings, VALENSA assisted the client in accurately calculating the required tile quantities, and provided professional product selection recommendations according to different application areas and budget requirements. We also developed a comprehensive supply and delivery plan to ensure smooth execution.

During the project, when the client requested additional materials, VALENSA responded promptly by coordinating with the factory to arrange production and shipment, ensuring timely delivery and preventing any impact on the construction schedule.

As this was our first collaboration, a minor issue occurred: the tile dimensions delivered did not fully match the project’s requirements. Upon receiving feedback, we immediately adjusted the production schedule, prioritized the client’s order, and implemented corrective actions. Through proactive communication and efficient coordination, we successfully completed the delivery ahead of the agreed timeline.

Strong production capacity, a stable supply system, consistent product quality, and a proactive problem-solving attitude are the key reasons why VALENSA has maintained long-term partnerships with clients for more than a decade.

When Buying Porcelain Tiles from China Makes Sense in 2026

Based on the above analysis, it is evident that Chinese tile suppliers rank among the world’s leading players in terms of production capacity, supply stability, product quality, design innovation, integrated solution capabilities, and after-sales issue handling.

Amid ongoing changes in the export environment, Chinese tile suppliers are actively embracing transformation and adaptation. They are no longer focused solely on product supply, but are increasingly committed to a customer-centric service philosophy, delivering professional, efficient, and value-driven services that create long-term value for their clients.

If you have the following requirements, sourcing tiles from China remains your optimal choice:

You Need Stable Bulk Supply

Chinese factories are still among the best options for:

- Container-level orders

- Repeated bulk purchases

- Multi-SKU supply under one roof

You Value Manufacturing Experience

Factories with 15–20+ years of production experience tend to:

- Control technical details better

- Maintain consistent standards

- Adapt faster to buyer feedback

This reduces hidden costs over time.

You Choose Factory Direct Cooperation

Working directly with a porcelain tile factory helps buyers:

- Reduce communication layers

- Improve lead time control

- Build long-term supply stability

This approach is increasingly preferred by professional wholesalers in 2026.

Conclusion

So, is buying porcelain tiles from China still a good idea in 2026?

The answer is yes!

China remains one of the most competitive sources for porcelain tiles. However, success today depends less on price and more on factory selection, capability evaluation, and long-term cooperation mindset.

Buyers who focus on reliable factories rather than cheap offers are far more likely to achieve stable supply and sustainable growth.

If you are sourcing porcelain tiles for wholesale or long-term distribution, working directly with an experienced factory can significantly reduce risk and improve supply stability.Choosing the right manufacturing partner matters more than ever in 2026.

Looking to collaborate? Click the link below to contact VALENSA.

https://www.valensaceramics.com/inquiry/